Advancements in Lithium Cell Manufacturing Plants

The surge in demand for lithium-ion batteries, driven by the growing electric vehicle market and the increasing adoption of renewable energy storage solutions, has propelled the evolution of lithium Cell Assembly machine. These state-of-the-art facilities are at the forefront of innovation, transforming the landscape of energy storage technology. Here's an exploration of the key components and advancements within Lithium Cell Manufacturing Plants:

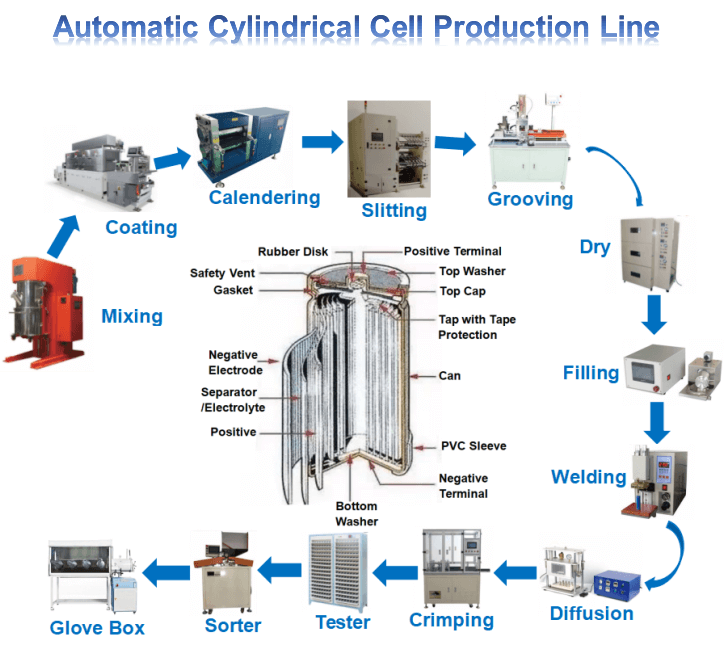

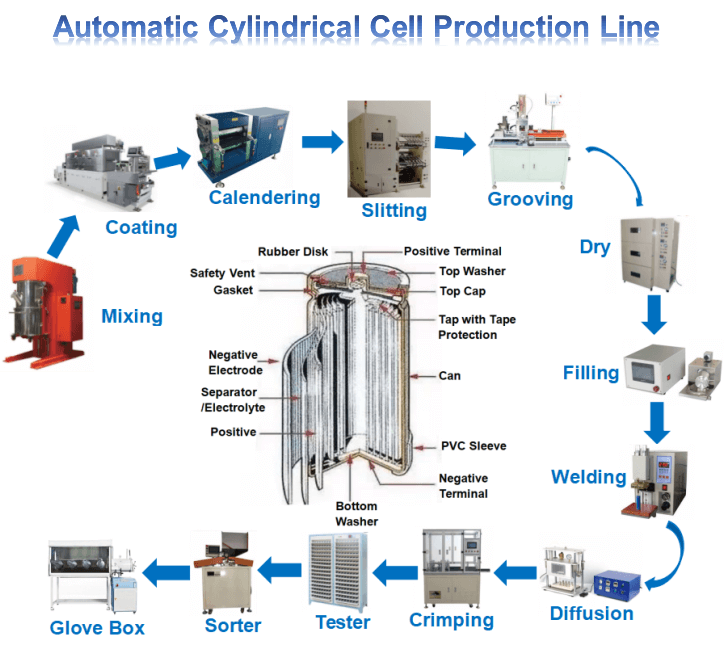

1. Automated Production Lines:

Lithium Cell Manufacturing Plants are embracing automation to enhance efficiency and precision in the production process. Automated production lines ensure consistent quality and reduce the margin of error, leading to higher yields and reliability in lithium cell production.

2. Sustainable Practices:

Sustainability is a key focus in modern Lithium Cell Manufacturing Plants. These facilities integrate eco-friendly practices, such as recycling processes and the use of renewable energy sources, to minimize their environmental footprint. This commitment to sustainability aligns with the global push for greener energy solutions.

3. Improved Electrode Manufacturing:

The heart of any lithium-ion battery lies in its electrodes. Lithium Cell Manufacturing Plants are investing heavily in advanced electrode manufacturing technologies. Precision coating, calendering, and drying processes contribute to the production of electrodes with optimized thickness, porosity, and density.

4. Roll-to-Roll Calendering:

The adoption of Roll-to-Roll (R2R) calendering machines has revolutionized the electrode manufacturing process. This continuous and scalable method ensures uniform thickness and density of electrode materials, resulting in batteries with enhanced performance and energy density.

5. Quality Control and Testing Stations:

Rigorous quality control measures are integrated into Lithium Cell Manufacturing Plants. Automated testing stations monitor key parameters such as voltage, capacity, and cycle life, ensuring that each lithium cell meets stringent quality standards before entering the market.

6. Energy-Efficient Design:

Lithium Cell Manufacturing Plants are incorporating energy-efficient designs to optimize resource consumption. From intelligent lighting systems to energy recovery mechanisms, these facilities are committed to reducing energy consumption and operational costs.

7. Research and Development Facilities:

The dynamic nature of battery technology requires continuous research and development. Lithium Cell Manufacturing Plants often house dedicated R&D facilities to explore new materials, cell chemistries, and manufacturing techniques. This commitment to innovation drives the evolution of lithium cell technology.

8. Scalability and Modular Design:

Scalability is a crucial consideration in lithium Cell making machine. The modular design of these facilities allows for flexible expansion or modification, accommodating the increasing demand for lithium cells in various applications, from consumer electronics to electric vehicles.

9. Integration of Industry 4.0 Technologies:

Industry 4.0 technologies, including the Internet of Things (IoT), artificial intelligence, and data analytics, are increasingly integrated into Lithium Cell Manufacturing Plants. These technologies enhance real-time monitoring, predictive maintenance, and overall efficiency in production processes.

10. Collaboration and Global Supply Chains:

- Lithium Cell Manufacturing Plants often engage in collaborative efforts and form global supply chains to secure a stable supply of raw materials, share expertise, and meet the growing demand for lithium-ion batteries on a global scale.

In conclusion, Lithium Cell Manufacturing Plants are pivotal in advancing energy storage technologies. Their commitment to automation, sustainability, innovation, and scalability reflects the industry's determination to meet the challenges of a rapidly evolving energy landscape. As these plants continue to evolve, they play a vital role in shaping the future of renewable energy and electric mobility.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported