Practical Applications of Lithium Cell Pilot Lines

Lithium Cell Pilot Lines serve crucial practical purposes, especially in the research and development phase of battery technology and the validation of novel battery manufacturing processes. Here are some practical applications of Lithium Cell Packing Lines:

Validation of New Technologies:

Lithium Cell Pilot Lines provide a platform for researchers to validate the feasibility of new battery technologies. This includes innovations in electrode materials, electrolyte formulations, and battery structure designs. Through small-scale production experiments, researchers can assess the performance and stability of emerging technologies.

Electrode Material Development:

On Lithium Cell Pilot Lines, researchers can explore different electrode materials and coating processes. This helps optimize the structure of electrodes, enhancing battery energy density, cycle life, and overall performance.

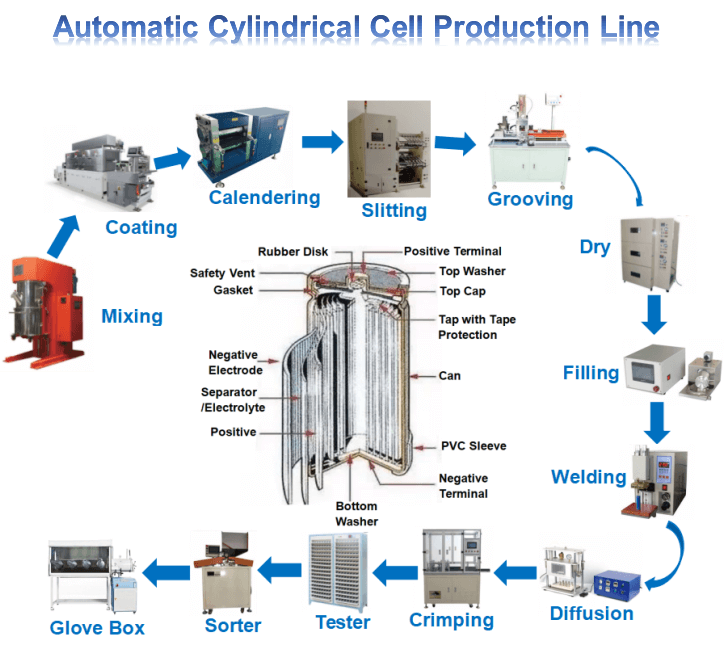

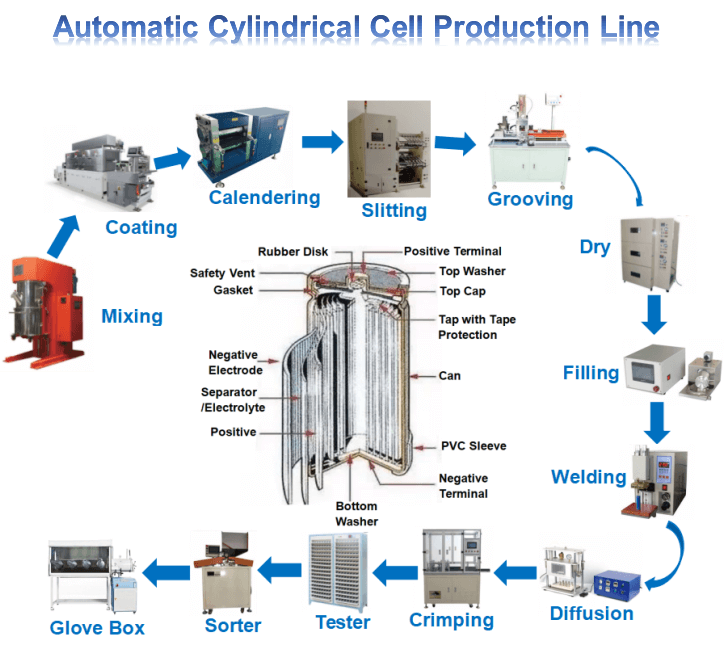

Optimization of Process Parameters:

By experimenting with and adjusting the production processes on Lithium Cell Pilot Lines, researchers can optimize various parameters. This involves key steps such as electrode coating, drying, and pressing, ensuring battery consistency and quality.

Verification of Battery Designs:

When designing new batteries, Lithium Cell Pilot Lines offer a testing ground for these designs. Researchers can manufacture small-scale battery samples, evaluate their performance, and adjust designs based on experimental results.

Innovation in Production Processes:

Lithium Cell Pilot Lines can be used to test and validate innovative production processes. This may include new coating technologies, battery assembly methods, electrolyte injection systems, and more. Through these experiments, the optimal manufacturing processes can be determined to improve production efficiency.

Small Batch Production:

In the early stages of product development, Lithium Cell Pilot Lines allow for small-scale batch production. This is crucial for meeting market demands, conducting market tests, and showcasing conceptual products to potential customers.

Rapid Iteration and Adjustments:

Lithium Cell Pilot Lines offer flexibility, enabling researchers to conduct experiments, adjust production parameters quickly, and iterate within short timeframes. This flexibility accelerates the development cycle of new technologies and processes.

Risk Management Prior to Scaling Up:

Before scaling up to large-scale production, Lithium Cell Pilot Lines can be used for risk management. Identifying and resolving issues through small-scale production helps mitigate risks associated with introducing new technologies into large-scale manufacturing.

In summary, the practical applications of Lithium Cell Pilot Lines are geared towards innovation and research in the battery manufacturing field. They provide a platform for researchers to test and validate new concepts, technologies, and processes, driving advancements in battery technology and the development of future products.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported