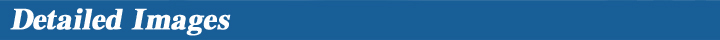

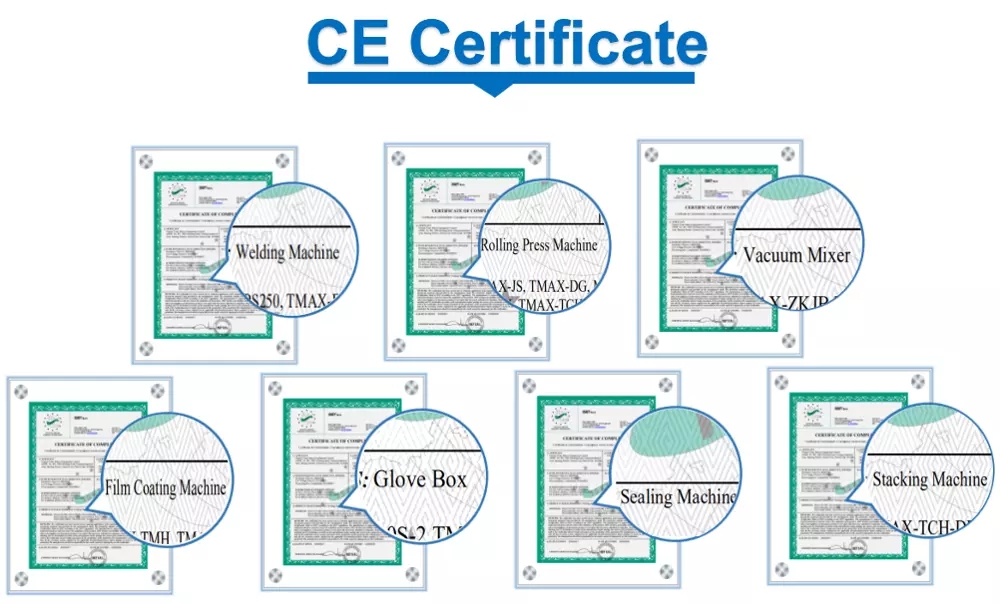

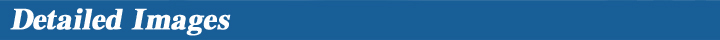

Automatic Winding Machine For Cylindrical Cell Production

1. Device Description

The equipment is used for the production of cylindrical lithium-ion battery cells and is one of the key equipment for battery production. The working process is roughly as follows: after the active unwinding, the positive and negative pole pieces and diaphragms made by the film making mechanism go through tension control, dust removal, process deviation correction, iron removal, diaphragm electrostatic removal, quality monitoring and other operations, and enter the winding part under the guidance of the guide wheel and pole piece guide mechanism. After the winding production is completed, the electric core is removed by the manipulator for short-circuit detection, and is sent to the collection platform by the conveyor belt after photoelectric counting. If nonconforming products are detected during the manufacturing process, they will be removed and entered into the nonconforming product collection box during the transportation process.

2. Incoming Material Requirements

2.1 Positive and Negative Plates

1) Tolerance of Wide Slitting

A: Within 0.1mm

Deviation of Coating Width Direction

Thickness: Within 3%

2) Waveform, Bending, Warping

No waveform (Refers to the defect of the end face);

Warping (After cutting, the pole piece of the cutting part curls);

Serpentine Error: The serpentine error of the length of the pole piece unit is less than 0.3mm/1m.

3) Red or green and other obvious color tapes shall be used for tape connection to facilitate

detection, and a single roll shall be discharged at the winding place.

4) Final Marking: The signal used up as the material of the original reel and the uncoated part

of the terminal are more than 1m.

2.2 Isolating Membrane

1) Slitting Width Tolerance: ± 0.05mm

2) Visual judgment of waveform, bending and skirt shape is excluded.

3) Final Marking: The final mark can be marked in green or black for the signal of exhaustion

3. Technical Specifications and Functions

3.1 Applicable Material Specifications

|

Width range of electrode piece (excluding tab)

|

9-80mm

|

|

Exposed length of tab

|

8-25mm

|

|

Length of electrode piece unit

|

150- 1500mm

|

|

Electrode piece unwinding diameter

|

φ400mm

|

|

Needle diameter

|

1.8-6mm(Equipped with 3mm diameter needle for the first time)

|

|

Unwinding diameter of separator

|

φ300mm

|

|

Separator width range

|

10-75mm

|

|

Winding diameter

|

φ6mm-φ20mm

|

|

Inner diameter of unwinding core

|

φ76.2mm

|

|

Termination tape

|

Winding the battery for half a cycle to a cycle and a half

|

|

Termination tape width

|

20-60mm

|

|

Inner diameter of winding core of terminating tape

|

76.2mm

|

4. Technical Parameters of Equipment

Electrode Piece Cutting Burr: Transverse cutting burr is less than 30 μ m. Longitudinal cutting burr is less than 15 μ m.

Cell Alignment Positive / negative plate: ≤± 0.5

Negative plate / diaphragm: ≤± 0.5

Diameter ofjelly roll: ≤± 0.20mm

Pass rate: ≥ 99.0%

The ratio of the number of good products to the total number of production (Eliminate the defects caused by non equipment reasons)

Operation Rate: ≥ 95% Ratio of actual production quantity to theoretical production quantity (Excluding downtime caused by non equipment reasons).

Productivity: (φ 10) 5- 12ppm /250mm long electrode piece

Working tension of positive and negative plates: 20N adjustable (Can be set manually and directly on the touch screen)

Diaphragm working tension: 18N adjustable (It can be set manually and directly on the touch screen)

5. Equipment installation and commissioning instructions

Air supply pressure: 0.5mpa Air demand flow: 100L/min

Power supply: Three-phase 380V 50Hz

Power: 10kw

Weight: 2000kg

Ambient temperature: -40 ° ~+45 °

Relative humidity: ≥ 60%

Overall dimension: L2800mm * H1700mm * W1350mm

Coating color: According to customer requirements

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported