The development of a lithium battery lab line involves several key stages, reflecting advancements in technology, materials, and processes. Here's an overview of the typical progression:

Early Development:

Materials Research: Initial stages involve research into electrode materials, electrolytes, and separator technologies. Scientists and engineers explore various compositions to enhance performance, safety, and energy density.

Prototyping: Small-scale pilot lines are established to test new concepts, materials, and manufacturing processes. This phase allows for the identification of challenges and optimization of production methods.

Scale-Up and Lithium cell manufacturing machine :

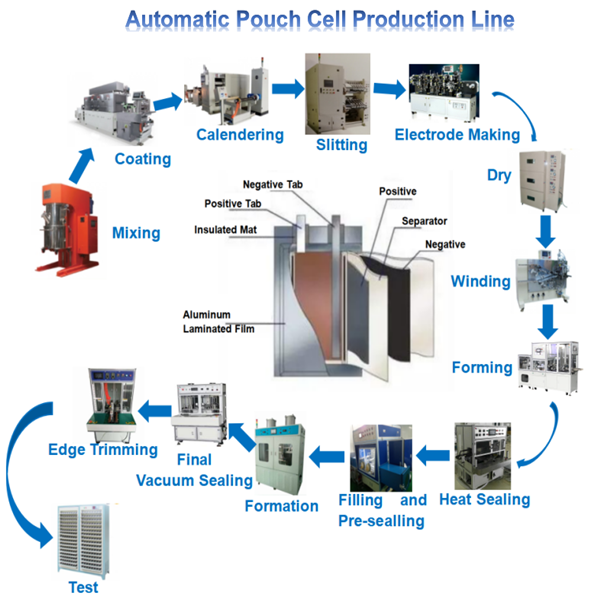

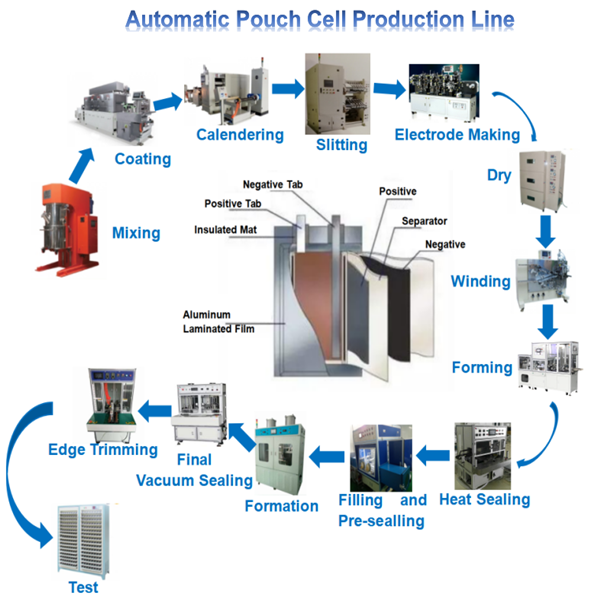

Pilot Line Establishment: Based on successful prototyping, a pilot line is set up to test the scalability of production processes. This involves larger-scale equipment and closer approximation to full-scale manufacturing conditions.

Process Optimization: Engineers fine-tune manufacturing processes, addressing challenges related to coating, calendaring, winding, assembly, and quality control. This phase aims to establish efficient and reliable production methods.

Technology Advancements:

Incorporation of Advanced Technologies: As the industry evolves, the plant integrates state-of-the-art technologies, such as automation, robotics, and artificial intelligence, to enhance precision, efficiency, and safety in the manufacturing process.

Energy Efficiency: Emphasis is placed on optimizing energy consumption and waste reduction. Sustainable practices and environmentally friendly manufacturing processes are explored.

Capacity Expansion:

Full-Scale Production: Upon successful pilot line operations, the fabrication plant undergoes expansion to reach full-scale production. This involves larger production lines with increased throughput to meet market demand.

Quality Assurance: Rigorous quality control measures are implemented at every stage of production to ensure the consistency and reliability of the manufactured Lithium cell fabrication machine.

Diversification and Customization:

Product Diversification: The plant may expand its product range to include a variety of lithium cells catering to different applications, such as consumer electronics, electric vehicles, and energy storage.

Customization: Flexible manufacturing processes allow for customization of lithium cells to meet specific requirements of clients or industries.

Research and Development (R&D) Center:

Establishment of R&D Facilities: The plant may establish a dedicated research and development center to continuously innovate and stay at the forefront of battery technology.

Collaboration with Research Institutions: Partnerships with universities and research institutions foster ongoing exploration of cutting-edge materials and technologies.

Global Market Presence:

Market Expansion: Successful lithium cell fabrication plants expand their presence globally, establishing manufacturing facilities in strategic locations to meet regional demand.

Regulatory Compliance: Adherence to international standards and regulations becomes crucial to ensure product safety and market access.

Industry Collaboration:

Collaboration with OEMs: Strong partnerships with original equipment manufacturers (OEMs) and other stakeholders help align production with market needs.

Supply Chain Integration: Integration with upstream suppliers and downstream distributors creates a streamlined and efficient supply chain.

Continuous Improvement:

Iterative Optimization: Continuous improvement initiatives, informed by data analytics and feedback loops, ensure that the fabrication processes remain efficient, cost-effective, and environmentally sustainable.

Adoption of Emerging Technologies: Integration of emerging technologies, such as solid-state battery technology, to stay competitive and address evolving market demands.

The development of a lithium cell fabrication plant is an iterative process that involves a combination of research, pilot testing, scale-up, and ongoing optimization to meet the dynamic demands of the global battery market.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported