Innovations in Lithium Cell Production Machines

Introduction

The evolution of lithium-ion batteries has been instrumental in powering a wide range of modern devices, from smartphones to electric vehicles. Behind this technology lies the intricate world of lithium cell production machines, which have played a pivotal role in advancing battery manufacturing.

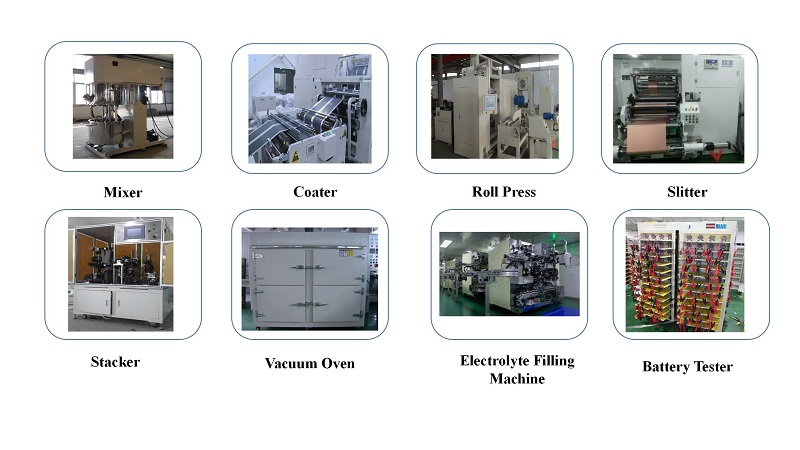

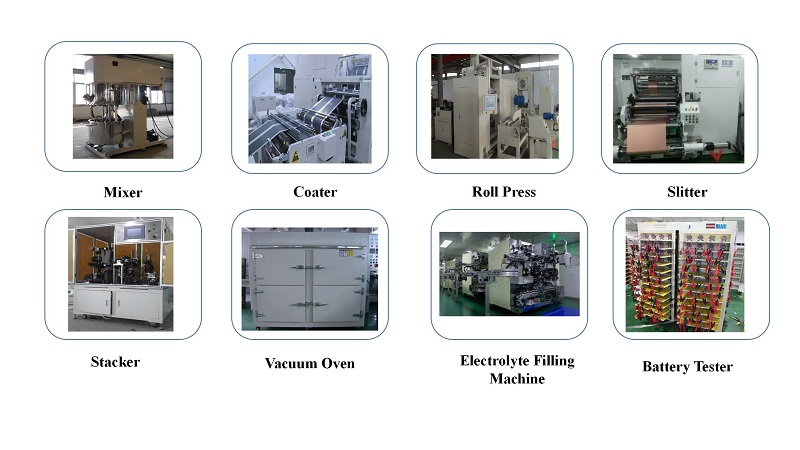

Lithium Cell Production Machines: A Glimpse

Lithium cell production machines are specialized equipment designed for the manufacturing of lithium-ion batteries. These machines are engineered to handle various processes involved in battery production, ensuring precision and efficiency at every stage.

Key Components and Functions

Coating Machines: These machines are responsible for applying the electrode materials onto metal foils. They play a vital role in determining the battery's energy density and performance.

Assembly Lines: Lithium cell assembly lines are designed to put together the various components of the battery, including electrodes, separators, and electrolytes, in a controlled and precise manner.

Winding Machines: In cylindrical battery production, winding machines are used to create the characteristic cylindrical shape by rolling the electrode-separator-electrode layers into a compact form.

Calendaring Machines: Calendaring machines ensure that the electrodes are uniformly compressed to the desired thickness, improving the overall quality of the battery.

Spot Welders: These machines are used for welding the battery tabs, connecting the anode and cathode to the external terminals.

Formation and Testing Equipment: Formation equipment plays a crucial role in conditioning and testing batteries to ensure they meet performance and safety standards.

Advancements in lithium Cell Assembly machine

Automation: Automation and robotics have significantly improved the precision and speed of battery production. Robots can handle delicate tasks with accuracy, reducing human errors.

Improved Coating Technology: Coating machines have seen advancements in precision and material utilization, leading to higher energy density and longer battery life.

Energy Efficiency: Modern lithium cell production machines are designed to be energy-efficient, reducing the environmental footprint of battery manufacturing.

Quality Control: Enhanced testing and quality control equipment ensure that batteries meet stringent safety and performance standards.

Applications

Consumer Electronics: Lithium cell production machines are used for manufacturing batteries for smartphones, laptops, and other portable devices.

Electric Vehicles: The production of high-capacity lithium-ion batteries for electric vehicles relies on advanced production equipment.

Energy Storage Systems: Lithium-ion batteries are also crucial components in energy storage systems, where production machines ensure reliability and efficiency.

Conclusion

Lithium cell production machines have played a pivotal role in the widespread adoption of lithium-ion batteries across various industries. These machines continue to evolve, making batteries more efficient, cost-effective, and environmentally friendly. As technology advances further, we can expect even more innovations in lithium cell production machines, contributing to the development of cleaner and more sustainable energy solutions.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported