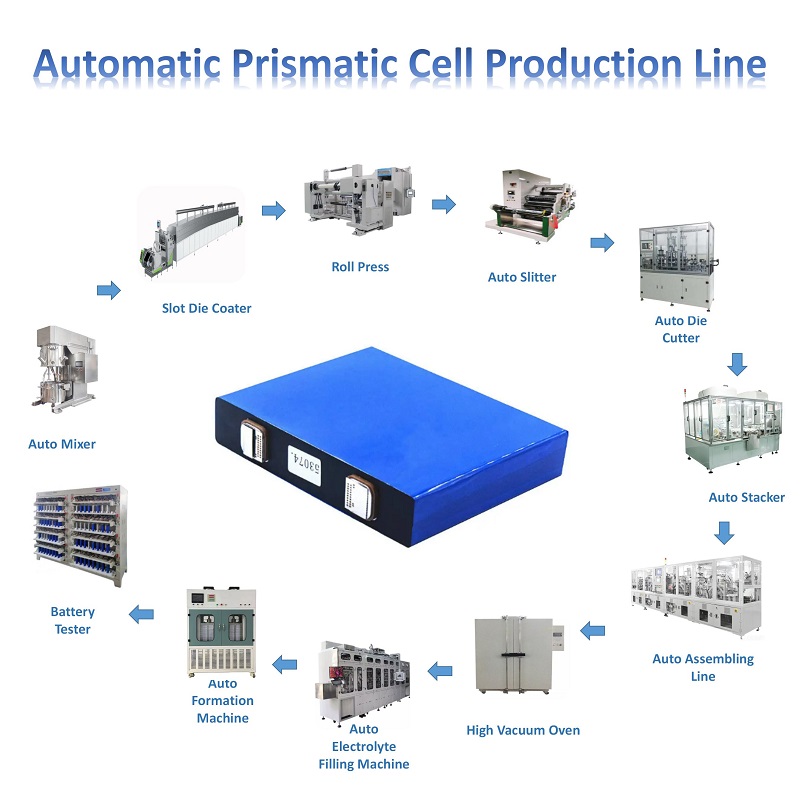

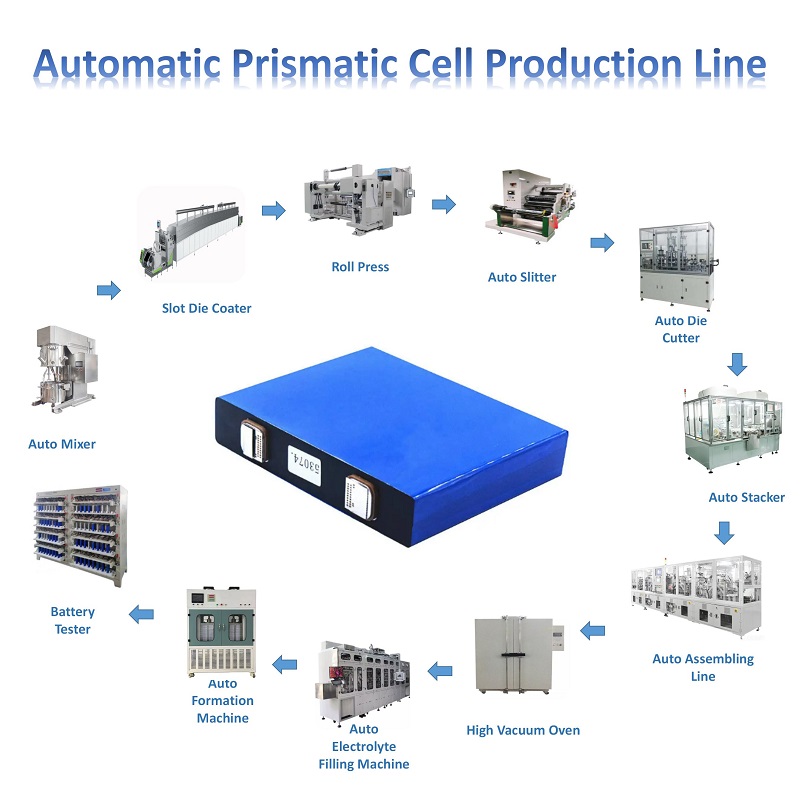

A prismatic battery assembly line is an industrial machine used for the automated manufacturing of prismatic (rectangular or square) lithium-ion battery cells. Prismatic cells differ from cylindrical cells like the 18650 in shape and are often used in various applications, including electric vehicles and energy storage systems. The assembly machine is designed to perform multiple tasks in the production process of these cells. Here are some of its key functions:

Electrode Manufacturing: The machine can include equipment for manufacturing positive and negative electrodes. This involves applying electrode materials to current collectors, typically made of copper and aluminum foils, and then cutting them into the required shapes and sizes for the prismatic cells.

Separator Handling: Separators are delicate components that are essential for preventing short circuits in battery cells. The machine can handle and position separators accurately during the cell assembly process.

Cell Stacking: Prismatic cells consist of multiple layers of positive and negative electrodes separated by separators. The machine stacks these layers in the correct order and orientation.

Electrolyte Filling: Electrolyte, which is a critical component of lithium-ion cells, is filled into the assembled cell to allow for ion movement between the electrodes during operation. The machine can precisely control the electrolyte filling process.

Sealing: The machine seals the prismatic cell to ensure it is airtight and safe for use. This process is crucial for preventing leaks and maintaining the integrity of the cell.

Formation and Testing: After assembly, the cells often undergo formation and testing processes to ensure they meet specific performance and safety criteria. This may include cycling the cells through charge and discharge cycles to stabilize their performance.

Quality Control: The machine can incorporate quality control measures to identify and reject defective cells, ensuring only high-quality cells are shipped.

Data Collection: Throughout the assembly process, data related to cell performance, dimensions, and other parameters may be collected for quality assurance and process optimization.

Prismatic cell scale plant are crucial for automating the production of prismatic lithium-ion cells, which are widely used in electric vehicles, consumer electronics, and energy storage systems. These machines enable efficient and consistent manufacturing, contributing to the development and growth of battery-powered technologies.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported