Prismatic cells are a type of lithium-ion battery that is rectangular in shape and is widely used in various applications such as electric vehicles, energy storage systems, and portable electronic devices. To meet the increasing demand for prismatic cells, specialized production machines have been developed to manufacture them efficiently and with high quality. In this article, we will take a closer look at prismatic cell production machines, their key features, and production process.

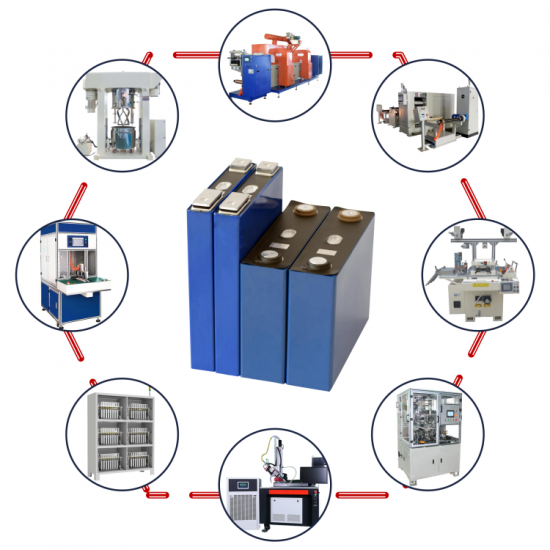

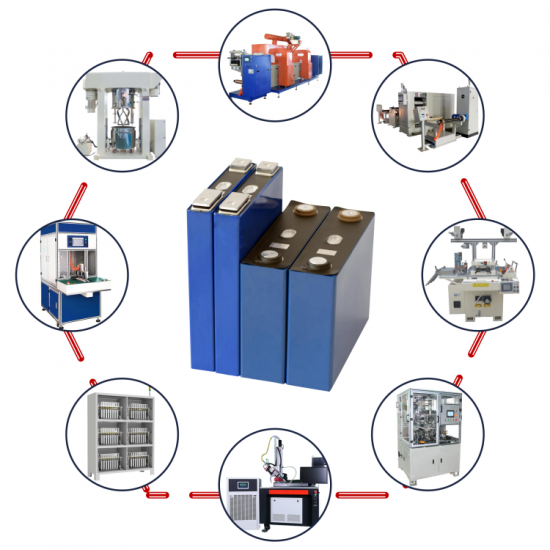

The production design machinery and equipment of a square battery production machine typically includes a Battery Slitter Slitting Machine for cutting electrode material into the desired shape and size, a Film Coater Coating Machine for applying the active material onto the electrodes, a Hot Rolling Press Calendering Machine for compressing the electrodes to the desired thickness, a Prismatic Cell Stacking Machine for assembling the electrodes into the desired configuration, and a welding machine for connecting the electrodes to the current collector tabs. The machine also requires a battery electrolyte filling system for adding the electrolyte to the cell, a vacuum sealing machine for sealing the cell, and a battery testing system for measuring the performance and safety of the cell. In addition, a quality control system is also necessary to ensure the consistency and reliability of the production process.

Production Process:

The production process for prismatic cells involves several steps including electrode manufacturing, electrode coating, cell assembly, and testing. Prismatic cell production machines are designed to automate these processes to increase efficiency and reduce errors. The machines are typically modular and can be customized to meet specific production requirements. Let's take a closer look at each of these processes.

Electrode Manufacturing: This process involves the production of positive and negative electrodes that will be used in the prismatic cell. The electrode material is typically coated on a current collector substrate. Electrode manufacturing machines are used to cut the current collector material to size, coat it with the electrode material, and dry it.

Electrode Coating: The coated electrode material is then transferred to the electrode coating machine, which is designed to apply a uniform layer of electrode material on the current collector substrate. The thickness of the electrode material layer can be adjusted to meet specific requirements.

Cell Assembly: Once the electrodes are ready, they are assembled into a prismatic cell. The cell assembly machine is designed to automate the process of stacking the electrodes, adding separators, and winding the cell. The cell is then inserted into a prismatic cell casing, which is then sealed to prevent leakage.

Testing: The final step is to test the prismatic cell to ensure that it meets the required specifications. Testing machines are used to measure the voltage, capacity, and impedance of the prismatic cell.

Key Features:

Prismatic cell production machines have several key features that make them ideal for high-volume production. These include:

Modular Design: The machines are modular and can be customized to meet specific production requirements. This allows for a high degree of flexibility and ensures that the machines can be easily modified to meet changing production needs.

Automation: The machines are fully automated, which reduces errors and improves efficiency. This also ensures that the cells are produced consistently, which is critical for meeting quality requirements.

Precision: The machines are designed to be highly precise, which ensures that the cells are produced to the required specifications. This is critical for ensuring that the cells meet the required performance criteria.

Quality Control: The machines are equipped with quality control systems that monitor the production process and ensure that the cells are produced to the required standards.

In conclusion, prismatic cell production machines are critical for the efficient and high-quality production of prismatic cells. They are designed to automate the production process, reduce errors, and ensure that the cells are produced to the required specifications. With the increasing demand for prismatic cells in various applications, these machines play a critical role in meeting the production needs of the industry.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported