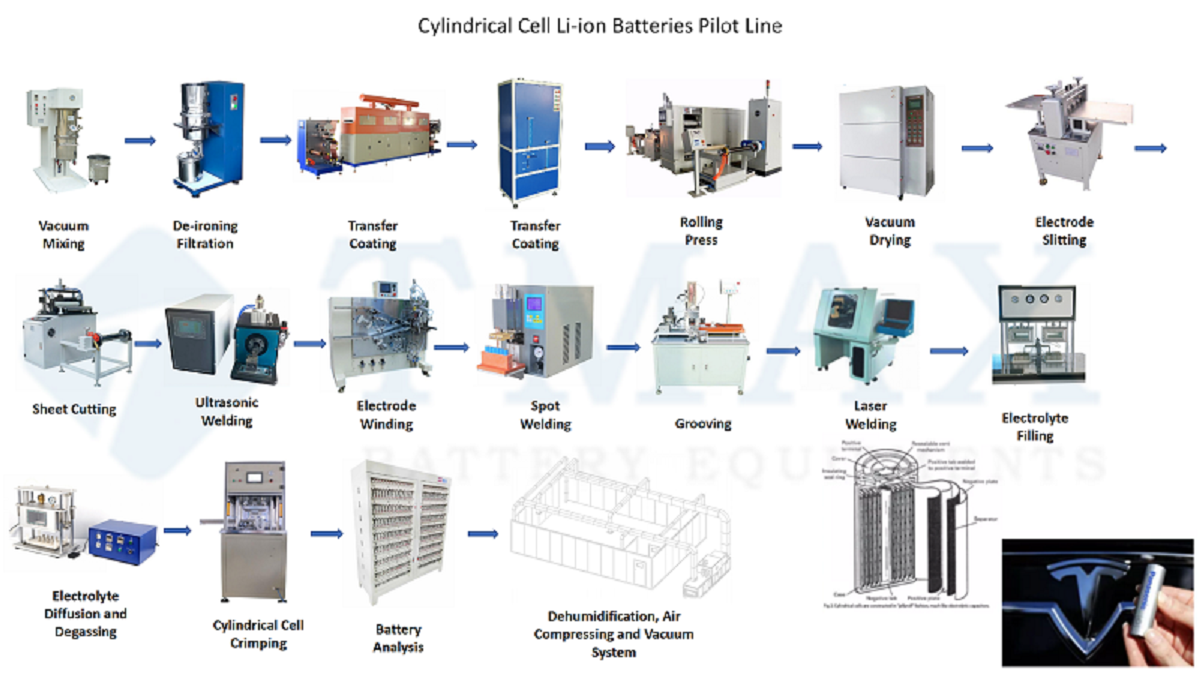

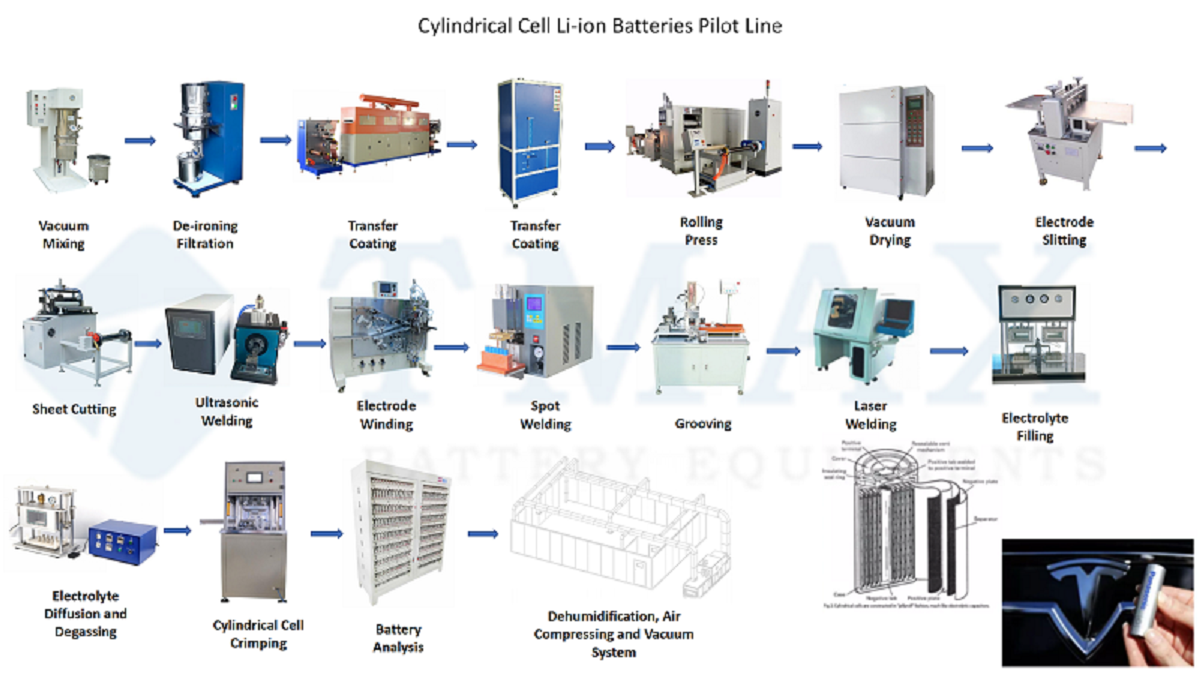

Cylindrical cell fabrication machine offers several advantages in the manufacturing of lithium-ion batteries:

Scalability: The equipment is designed to scale production efficiently, accommodating both small-scale pilot lines for research and development as well as large-scale manufacturing for mass production.

Uniform Coating: Coating machines provide precise and uniform application of electrode materials onto current collectors. This ensures consistency in the electrochemical performance of the cells, contributing to higher quality and reliability.

Versatility: Cylindrical cell fabrication equipment is versatile, supporting the production of various cell sizes and configurations. This adaptability allows manufacturers to meet diverse industry demands.

High Throughput: Automated winding or stacking machines, along with advanced assembly systems, enable high-throughput production, ensuring efficient manufacturing processes and meeting market demands for large quantities of cells.

Quality Control: The integrated testing and quality control equipment ensures rigorous evaluation of each cell's capacity, voltage, and other performance parameters. This contributes to the production of high-quality, reliable batteries.

Precision Welding: Tab welding machines provide precise and secure welding of metal tabs to the electrodes, ensuring reliable electrical connections and minimizing internal resistance.

Safety Assurance: Safety testing equipment simulates extreme conditions, such as overcharging and thermal stress, ensuring that cells meet stringent safety standards. This enhances the overall safety of the manufactured lithium-ion batteries.

Automation and Efficiency: Incorporation of automation systems, robotics, and artificial intelligence enhances efficiency and reduces the risk of errors in the manufacturing process. This results in improved productivity and cost-effectiveness.

Data-Driven Optimization: Data collection and analysis tools provide real-time insights into the manufacturing process. This data-driven approach allows for continuous optimization, ensuring consistent quality and identifying areas for improvement.

Advanced R&D Capabilities: The equipment facilitates advanced research and development activities with prototyping capabilities and the ability to experiment with innovative designs and materials, contributing to ongoing industry innovation.

Adherence to Industry Standards: Cylindrical Cell Lab line is designed to meet and exceed industry standards for Cylindrical Cell Assembly line. This ensures that the produced cells are compliant with safety and performance requirements.

Environmental Considerations: The latest equipment incorporates sustainable practices and environmentally friendly manufacturing processes, aligning with the industry's increasing focus on sustainability and reducing environmental impact.

In summary, cylindrical cell fabrication equipment excels in providing scalable, versatile, and high-throughput solutions with a strong emphasis on quality control, safety, and the integration of advanced technologies for efficient and environmentally conscious lithium-ion battery production.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported