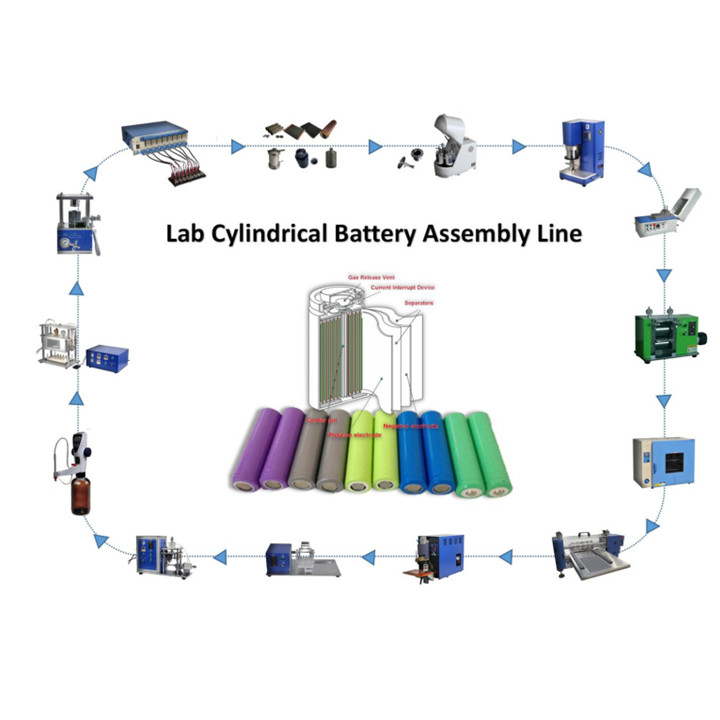

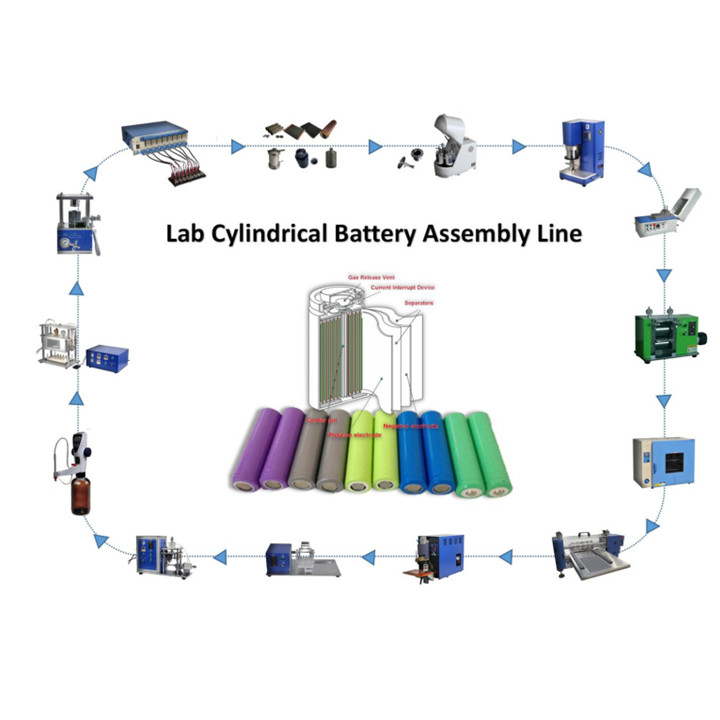

A Cylindrical Cell Production Plant equipped with online devices for lithium-ion battery production offers several advantages:

Real-Time Monitoring: Online devices enable real-time monitoring of various parameters during the manufacturing process, allowing researchers to gather immediate insights into the performance and quality of Cylindrical Cell manufacturing Plant

Continuous Data Collection: The continuous collection of data from online devices provides a comprehensive dataset that can be analyzed to identify trends, optimize processes, and make data-driven decisions for ongoing research and development.

Process Optimization: With real-time data, researchers can identify and address issues promptly, leading to continuous process optimization. This agility contributes to the refinement of manufacturing processes, enhancing efficiency and product quality.

Quality Control: Online devices facilitate continuous quality control by monitoring critical parameters such as coating thickness, winding tension, and electrolyte injection accuracy. This ensures that each cylindrical cell meets stringent quality standards.

Early Issue Detection: Immediate feedback from online devices allows for early detection of potential issues in the production line. This early warning system helps prevent defects and ensures the consistent quality of manufactured lithium-ion cells.

Remote Access and Control: The incorporation of online devices enables remote access and control, allowing researchers to manage and monitor the production process from anywhere. This flexibility is particularly beneficial for collaborative research and oversight.

Efficient Troubleshooting: In case of deviations or anomalies, online devices facilitate efficient troubleshooting. Researchers can quickly analyze data, identify the root cause of issues, and implement corrective measures without significant downtime.

Optimized Resource Utilization: Real-time data analytics aids in the optimized utilization of resources, minimizing waste and maximizing the efficiency of raw material usage, energy consumption, and overall production output.

Predictive Maintenance: Online devices contribute to the implementation of predictive maintenance strategies. By continuously monitoring equipment performance, researchers can anticipate maintenance needs, reducing the risk of unexpected breakdowns and optimizing equipment uptime.

Adaptability to Research Goals: The online nature of the equipment allows researchers to adapt the production line to specific research goals quickly. This adaptability is crucial for exploring new materials, designs, or production techniques in a dynamic research environment.

Enhanced Collaboration: Online devices promote collaboration by providing real-time access to data and insights. Researchers, engineers, and stakeholders can collaborate seamlessly, facilitating a more integrated and efficient research and development process.

Increased Visibility: The online nature of the equipment increases visibility into the entire production process. Researchers can track the progress of each cell, from materials processing to assembly, ensuring transparency and accountability.

In summary, the integration of online devices in a Cylindrical cell making Plant for lithium-ion battery production enhances the efficiency, quality, and adaptability of the research and manufacturing processes. The real-time capabilities contribute to data-driven decision-making, process optimization, and collaborative research efforts.

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported