Product model:TMAX-DSP-LBPBM05B

A. Functional Description:

This machine is mainly used for precise winding of cylindrical lithium-ion battery batteries.

The working process is as follows: the positive and negative plates are manually

introduced into the winding part, separated from the diaphragm, winded according to the technological requirements, automatically pasted the termination tape, and the core is automatically cut off.

B. Functions and Characteristics

1. The machine adopts a single needle structure.

2. Manual introduction of polar plates, automatic winding, automatic needle change,

automatic tape sticking and automatic blanking;

3. The tape is sticked horizontally (the end tape is perpendicular to the polar ear), the tape is smooth, the position of the tape can be precisely controlled and the core will not be tightened; the tape is stable and reliable;

4. The winding speed of the needle can be adjusted.

5. Active unwinding of two-roll diaphragm and tension proximity switch control

technology can automatically adjust tension during winding process.

6. The machine has a pole dust removal device.

7. Ending of diaphragm outsourcing;

8. The coiled cores are not damaged, core pulling and dislocation of the electrodes.

9. Easy to operate, easy to adjust and replace specifications.

C.Technological Process

The equipment meets the technological standard of winding cylindrical lithium ion

batteries: the diaphragm is completely wrapped with negative plates, and the negative plates are wrapped with positive plates. The process flow is as follows:

1. Prewinding of diaphragm: The length of prewinding diaphragm can be saved by using toothed knife technology.

2. Involving the negative pole: manually lead the negative pole piece into the winding part;

Involving the positive pole: manually lead the positive pole piece into the winding part;

3. Winding;

4. Shift of workstation;

5. Cut off the diaphragm, stick the stop glue and cut the material

D. Main Component Parts

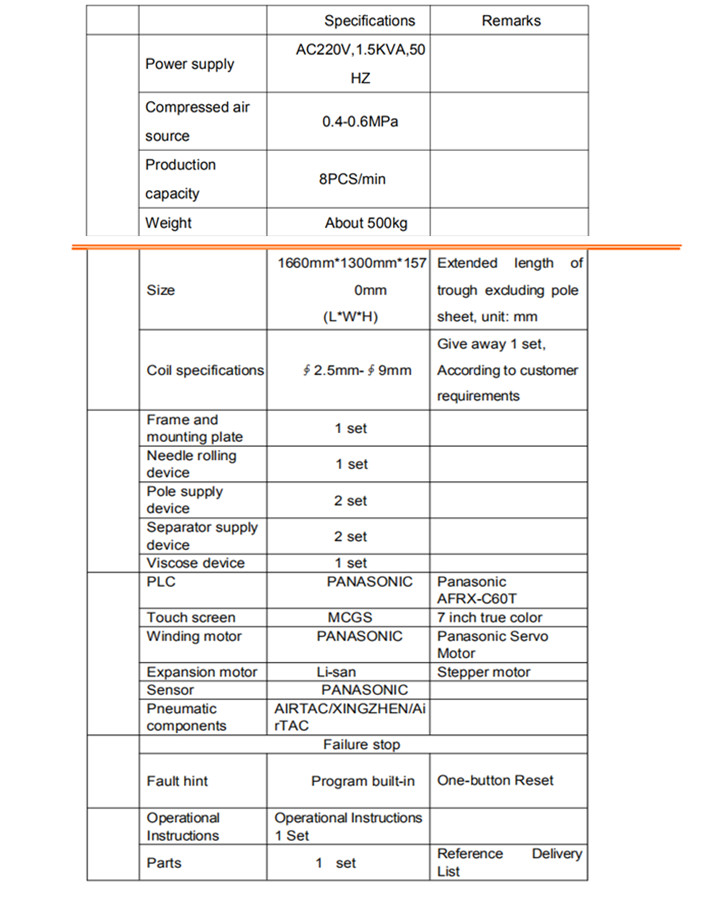

1. The equipment is composed of winding device, position changing device,diaphragm

unwinding device, polar plate guiding device, gluing device, blanking device and control system.

2. Winding device (2 sets): consisting of single-end pair-to-pair to ensure winding accuracy and easy to replaceneedles;

3. Position shifting device (1 set): for the conversion of winding and gluing positions;

4. Diaphragm unwinding device (2 sets): active unwinding air pressure control of diaphragm material roll;

5. Pole guide device (2 sets): unilateral adjustment, easy adjustment;

6. Sticking and blanking device (1set).

E. Technical Standard

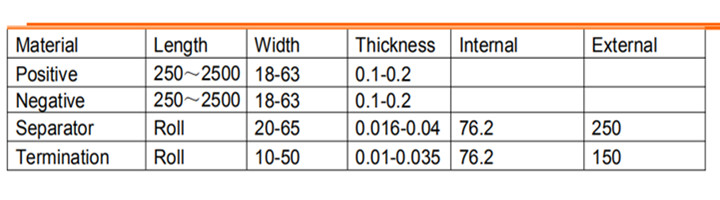

1. Diaphragm Width:20-65mm Rolling Needle Specification: 2.5-9mm, Pole Width

customized according tocustomer requirements: 18-63mm

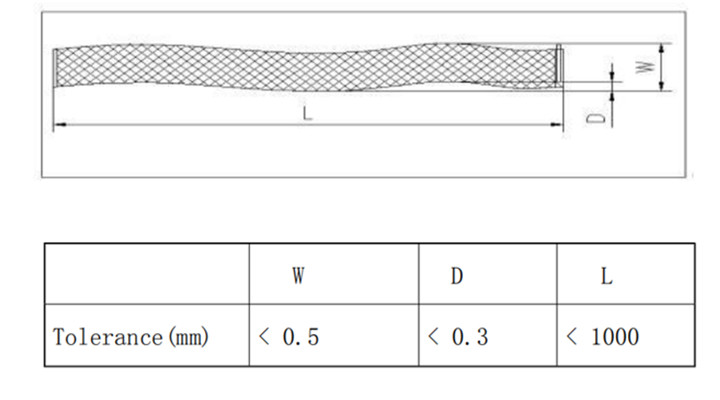

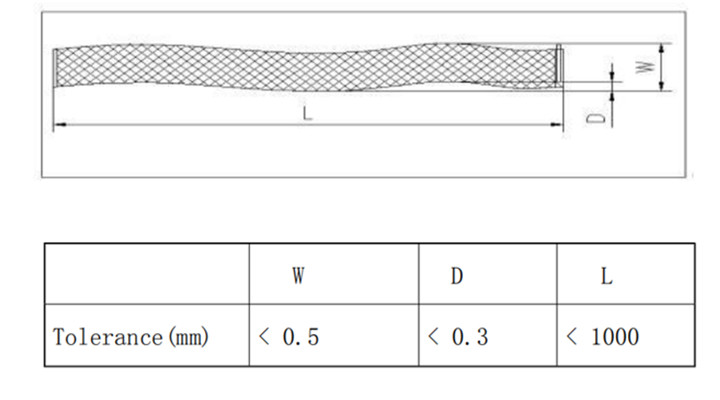

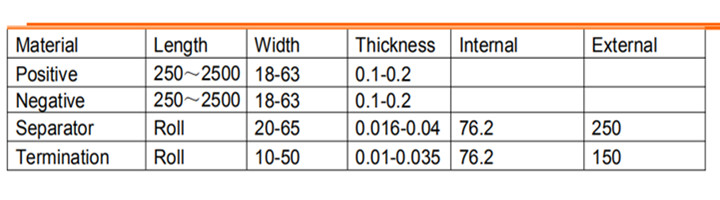

2. Material Specification Requirements (Unit:mm)

3. Applicable Core Outer Diameter(12mm-32_mm)

4. Equipment capacity: 6-15/min (according to the length/width of the polar plate)

5. Winding accuracy; when the pole meets the following conditions:

The width error of the polar plate is less than (+0.2 mm), and the bending error of the polar plate is less than (+1 mm/500 mm).

The error of coiling tower shape of diaphragm material is less than (+0.2mm).

The winding accuracy can be satisfied: the alignment error of diaphragm is less than

(+0.5mm), the alignment error of polar plate is less than (+0.5mm);

It can realize the positive pole wrapped in negative pole, the negative pole wrapped in diaphragm, and the alignment degree of finished product section (+0.5mm)

7. Qualification rate: > 98% (excluding non-equipment factors)

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported