Model TMAX-JK-DZF-6020

Application

It is used for drying, baking, melting wax and sterilizing crops such as factories, mining

enterprises, universities, scientific research and various laboratories.

I. Overview of Structure

DHG-202, 101 series of blast drying boxes (hereinafter referred to as drying boxes). The drying

box is composed of three parts: the box body, the electric heating blast system and the temperature

control system. The inner chamber (studio) and outer shell of the box are composed of

high-quality steel plate surface spraying treatment, bright color, beautiful and generous. The studio

is supported by mirror stainless steel plate or galvanized plate according to user's demand. The

height of the partition made of stainless steel wire can be adjusted indoors, and two pieces are

attached when leaving the factory (users need to add another order). Fill superfine glass wool

between inner and outer case as insulation layer. There is a large area of double-layer toughened

glass inspection window in the box, which can clearly observe the heating and drying items in the

box. The joint of the studio and the box door is equipped with a heat-resistant silicone rubber

sealing ring to ensure the tightness of the studio. Power switch, temperature display screen,

temperature controller and fan switch are all installed on the left side of the box for easy operation

and maintenance.

The electric heating blast system is composed of fan, air duct and electric heating parts. The

electric heating pipe (or electric heating wire), fan and other parts are installed at the bottom of the

studio.

The temperature control system consists of a temperature controller, a power tube (or electric

heating wire) and a temperature sensor.

II. Working Principle

The temperature controller is composed of intelligent digital control circuit composed of

integrated circuit devices and LED digital display circuit.

When K-type resistance is used as a sensor to measure the temperature in the working room, the

output resistance signal is proportional to the temperature (100_at 0 C). The signal is amplified by

the digital control circuit in the thermostat and sent one way to the LED display circuit to display

the measured temperature. The other way is sent to the comparator to compare with the set value.

When the two have positive deviation, the output resistance signal is proportional to the

temperature (100_at 0 C). Digital control circuit sends trigger signal, triggers bidirectional

thyristor conduction, and outputs electric power to heat the heating tube (or heating wire). When

the deviation decreases to zero, double high thyristor closes, stops output electric power, heating

tube (or heating wire) stops heating, and the output of heating in digital control circuit isWebsite: www.tmaxcn.com

controlled by PI. The D regulation mode has the functions of adjusting the output power and

correcting the linearity of the system temperature measurement.

The heating pipe (or electric heating wire) is installed at the bottom of the box body, and a fan (the

bottom of 101 blast drying box) is installed at the same time at the heating pipe (or electric heating

wire). When the machine is turned on, the fan is always in operation. Through impellers and air

ducts, the cold air flow in the working room flows in from all around, and the hot air flow flows

out from the middle, so that the indoor temperature is uniform.

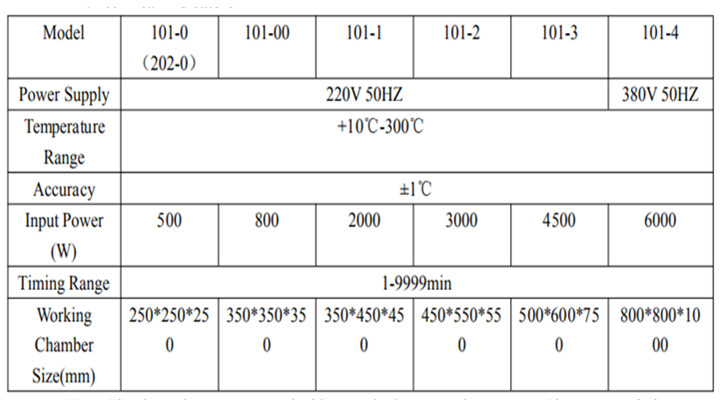

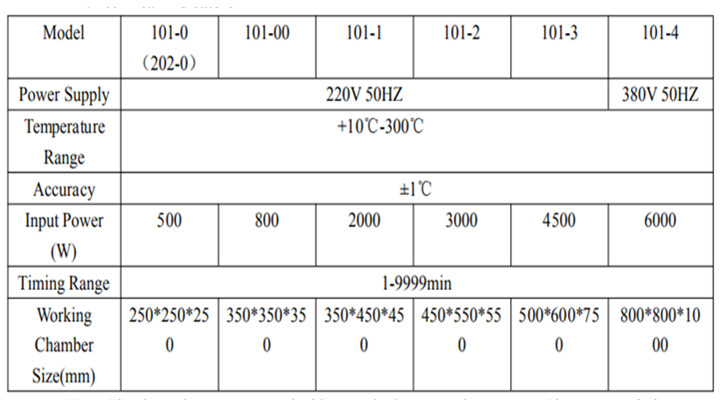

III. Technical Indicators

Note: The above data are measured with a standard mercury thermometer (the mercury tip is

placed in the geometric center of the working room) with an accuracy of 0.1 C and a relative

humidity of less than 85% at 25 C.

IV. Conditions of Use

1. Ambient temperature: 5-40 degrees Celsius

2. Relative humidity of air: not more than 85%

3. Power supply AC220V + 22V, frequency 50HZ + 1HZ, 380V (three-phase four-wire)

4. There is no corrosive gas, no strong vibration source and strong electromagnetic field around.

V. Usage

1. Put the articles that need to be dried into the drying box. There should be some space in the

upper, lower and around to keep the airflow in the working room unblocked and close the door of

the box.

2. Turn on the power supply and the fan switch. At this time, the power indicator light is on, the

motor is running, and the thermostat shows that after the "self-check" process, the PV screen

should show the temperature measured in the working room, and the SV screen should show the

setting temperature to be dried in use. At this time, the drying box will enter the working state.

3. After drying, if you need to continue replacing the drying articles, turn off the fan switch before

replacing the opening door to prevent the drying materials from blowing off. After replacing the

drying materials, close the box door, then open the fan switch, so that the drying box can enter the

drying process again. If you do not take out the articles immediately, turn off the blower first, and

then turn on the power switch. Turn off to keep the drying in the box. If you don't continue drying,

turn off the power switch. After the studio is cooled to room temperature, take out the drying items

in the box and dry the studio.

(Note: When taking out the drying box, be careful of scalds)

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported