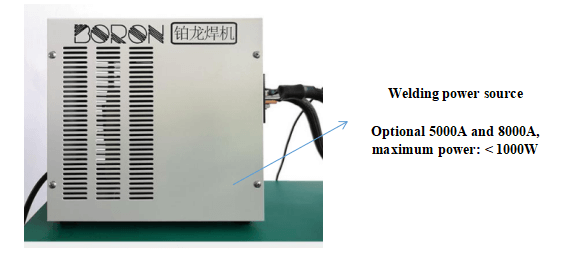

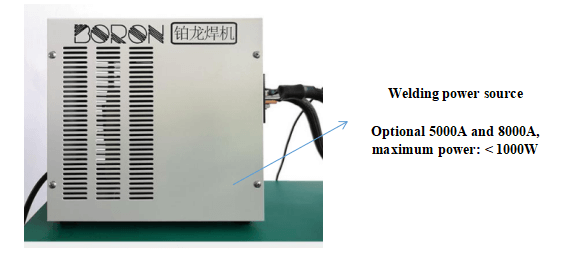

5000A or 8000A Medium Frequency Butt Welder/ Inverter Resistance Welder /Cylindrical Battery Power Battery Spot Welder for EV Battery

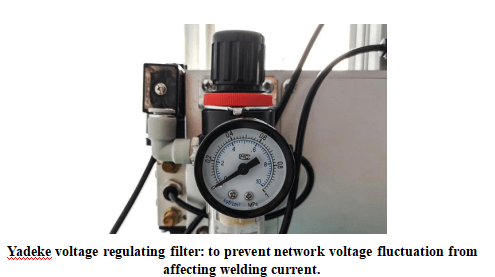

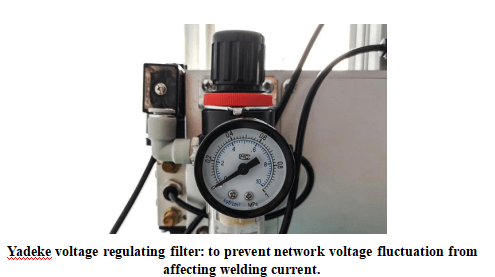

Inverter DC welding machine is a set of advanced welding equipment. The important components of this series of welding machine include inverter, welding controller and if transformer. It adopts modular design, imported components and advanced microcomputer multi-function controller. The controller adopts 8-bit micro-computer as the heart, combined with two groups of analog / digital conversion circuits, will automatically control the power supply voltage changes, environmental temperature changes, and maintain stable output.

Medium frequency inverter spot welding machine is an advanced welding equipment, which is widely used. The welding transformer has small volume and large output energy. The one-piece transformer welding tongs used in the automobile industry have more advantages.

The advantage is that the frequency of the welding transformer is increased from 50 / 60Hz to 2000Hz, which greatly reduces the weight of the iron core material. In addition, the rectifier diode in the secondary circuit of the transformer transforms the electric energy into DC power supply for welding. This can greatly improve the secondary circuit inductance value.

Features

1. DSP chip control, with two working modes of constant voltage command output and constant current output.

2. Using 1 microsecond primary sampling feedback is the real power supply with constant current operation mode in China.

3. The inverter bridge adopts soft switch technology to reduce switching loss and electromagnetic interference.

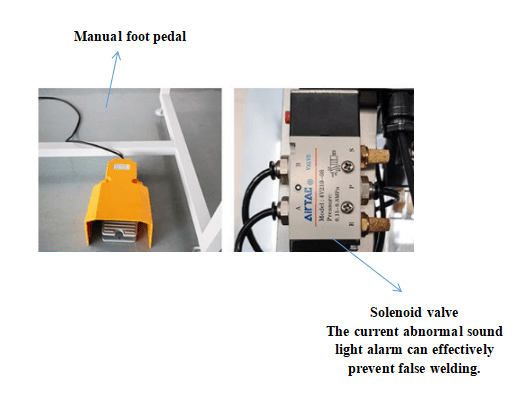

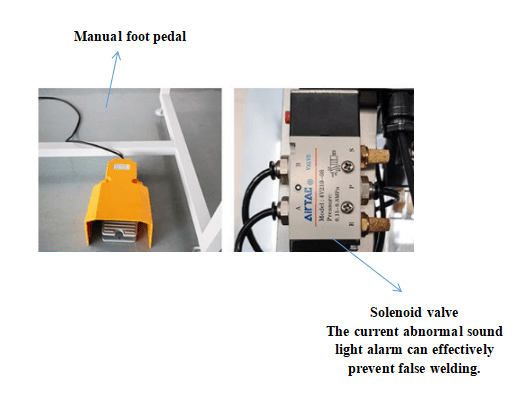

4. It has the functions of fault diagnosis and alarm, such as current abnormality, over limit of monitoring value, over limit of network voltage, over temperature, etc.

5. Complete IO and external communication functions, convenient for automatic welding, RS-232 data communication port.

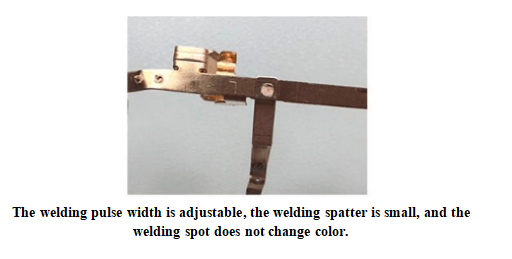

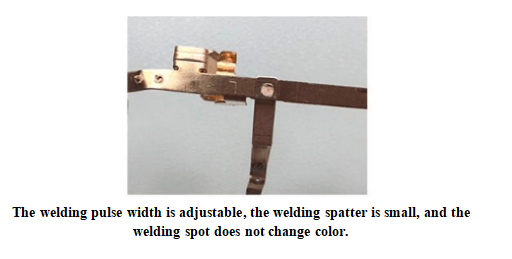

6. Three stage heating setting, with current slow rise and slow drop function and time wide range setting (1-999ms), effectively solves the problems of splashing during welding and quenching of workpiece after welding,

7.32 groups of parameters are stored for convenient switching of various welding varieties.

8. Counting function: with technical function, it can count the number of welding. With this function, you can easily understand the work efficiency.

9. It has the function of single point / continuous / seam welding.

10. It has the function of current rising / falling slowly: this function can avoid splashing during welding.

11. Judge whether the welding quality is good or not by setting the upper and lower limits of current and adding current waveform monitoring.

12. Three phase power input, intermediate frequency 4000Hz output after rectifier and inverter, high working frequency, small loss of transformer, obvious energy saving effect.

13. It is widely used in the welding of precision hardware such as battery connector, motor rotor, wire terminal, switch socket, resistance capacitance pin, sensor wire, electronic parts, temperature sensor, etc.

Specifications

|

Input power

|

AC380±10%, 50/60HZ

|

|

Power consumption

|

360W

|

|

Outline size

|

1000L*600W*1310H (mm)

|

|

Overall weight of equipment

|

110KG

|

|

Maximum output power of transformer

|

10KVA

|

|

Output voltage

|

9V

|

|

Inverter frequency

|

4KHZ

|

|

Welding time

|

1.0mS-20.0mS adjustable, accuracy: 0.1mS

|

|

Number of welding pulses

|

2

|

|

Welding needle configuration

|

1.8mm/3mm/6mm

|

|

Adjustable distance between welding needles

|

0-20mm

|

|

Welding speed

|

0.5-0.8S/single welding

|

|

Welding thickness

|

0.08-0.2mm nickel plated strip

|

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported